Why Hardtop 2.0?

As with every product, there is always room for improvement, right?? As we continue to work on more titles, we also experiment with materials and design changes that may improve our product!

In the first 7 years since we invented the Hardtop, we have carefully evaluated any issues brought to our attention. Some are artwork improvements (thank you to those who have pointed out areas to make better!). Some are issues that sometimes caused buckling and or lifting of the Hardtop due to temperature changes and/or high heat.

Heat is the main culprit behind most issues surrounding Hardtop installations.

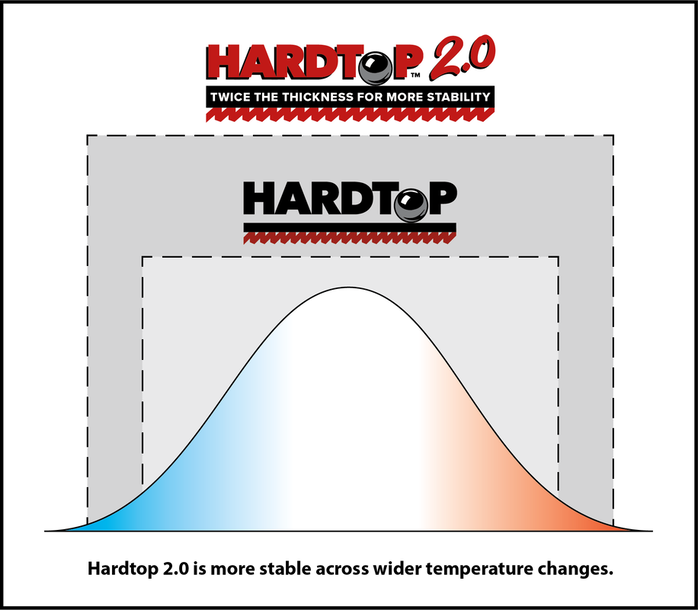

Most of our careful customers keep their machines in temperature-controlled environments, and follow our recommendation to use LED bulbs to reduce heat buildup. However, since that doesn't always happen, and large temperature swings sometimes cause buckling or lifting, we developed Hardtop 2.0 to be more stable than our original Hardtop when exposed to uncontrolled temperatures.

In the first 7 years since we invented the Hardtop, we have carefully evaluated any issues brought to our attention. Some are artwork improvements (thank you to those who have pointed out areas to make better!). Some are issues that sometimes caused buckling and or lifting of the Hardtop due to temperature changes and/or high heat.

Heat is the main culprit behind most issues surrounding Hardtop installations.

Most of our careful customers keep their machines in temperature-controlled environments, and follow our recommendation to use LED bulbs to reduce heat buildup. However, since that doesn't always happen, and large temperature swings sometimes cause buckling or lifting, we developed Hardtop 2.0 to be more stable than our original Hardtop when exposed to uncontrolled temperatures.

About your existing original Hardtops... If your machines aren't exposed to large, rapid temperature changes or prolonged high heat, then your original Hardtop should perform just as well as a Hardtop 2.0. We only developed 2.0 to address those edge cases related to excessive heat. While we still recommend staying within a reasonably controlled environment and reducing heat exposure, we now expect fewer issues in less controlled environments.

Here are a few of the temperature-related issues we've seen:

- Use of incandescent bulbs (in spite of our instructions for LED ONLY)

- Exposure to direct sunlight for a length of time (with glass installed which acts like a lens!). We have measured temperatures under the glass in excess of 145 degrees... 10 minutes AFTER removal from sunlight... so the Hardtop likely saw temperatures well over 200 degrees F!

- Large temperature swings in a game room. No HVAC control, or hot then A/C then hot again in the deep southern states in the US. We are not referring to 10-15 degree swings here — more like rapid 30-40 degree changes.

- Deeply cupped inserts with the Hardtop installed in a cool A/C environment... then taken outside for a long time in the heat of the summer. There is a tiny bit of air trapped between the Hardtop and cupped inserts. This air expands in high heat, which can push the Hardtop up creating a slightly raised area.

Here are a few of the temperature-related issues we've seen:

- Use of incandescent bulbs (in spite of our instructions for LED ONLY)

- Exposure to direct sunlight for a length of time (with glass installed which acts like a lens!). We have measured temperatures under the glass in excess of 145 degrees... 10 minutes AFTER removal from sunlight... so the Hardtop likely saw temperatures well over 200 degrees F!

- Large temperature swings in a game room. No HVAC control, or hot then A/C then hot again in the deep southern states in the US. We are not referring to 10-15 degree swings here — more like rapid 30-40 degree changes.

- Deeply cupped inserts with the Hardtop installed in a cool A/C environment... then taken outside for a long time in the heat of the summer. There is a tiny bit of air trapped between the Hardtop and cupped inserts. This air expands in high heat, which can push the Hardtop up creating a slightly raised area.

Once the temperature is controlled, these slightly raised areas usually go right back down. However, we have found it best to either fill deeply cupped inserts to eliminate that void space, or replace with new inserts.

By moving to a thicker, more dimensionally stable Hardtop (2.0) material, we can “widen” the margin for lifting up caused by the uncontrolled conditions we listed above. Also, our professional restorer/test installer actually liked the extra 1/32 thickness better (.79 mm, like a credit card), and he had no issues with switches and ramps.

The Hardtop (and now Hardtop 2.0!) is the most robust alternative that exists to revive a trashed/roached playfield at a fraction of the cost of a new playfield. We are proud of our product!

We have sold THOUSANDS of these to help restorers revive unplayable games into viable and beautiful machines that finally deserve a place again in anyone’s row of games. That is more than enough to keep us working on improvements and more titles!

By moving to a thicker, more dimensionally stable Hardtop (2.0) material, we can “widen” the margin for lifting up caused by the uncontrolled conditions we listed above. Also, our professional restorer/test installer actually liked the extra 1/32 thickness better (.79 mm, like a credit card), and he had no issues with switches and ramps.

The Hardtop (and now Hardtop 2.0!) is the most robust alternative that exists to revive a trashed/roached playfield at a fraction of the cost of a new playfield. We are proud of our product!

We have sold THOUSANDS of these to help restorers revive unplayable games into viable and beautiful machines that finally deserve a place again in anyone’s row of games. That is more than enough to keep us working on improvements and more titles!